Manufacturing Digital Transformation: The Key Role of MES in Automation Era

In the era of Industry 4.0, digital transformation in manufacturing is an inevitable step to increase productivity and operational efficiency. The Manufacturing Execution System (MES) plays a central role, providing connectivity, and monitoring of the entire manufacturing process. Let’s explore the importance of MES in synchronizing data, optimizing processes, and embracing the automation revolution.

1. Background and challenges faced by manufacturing businesses since 2020

Since 2020, the manufacturing industry has faced enormous challenges due to the COVID-19 pandemic, geopolitical tensions, and climate change. These factors have caused supply chain disruptions, material shortages, price increases, and fluctuations in market demand, posing significant difficulties for manufacturing businesses.

Here are some of the main challenges faced by manufacturing businesses:

Supply Chain Disruption: The COVID-19 pandemic has caused severe disruption to the global supply chain, leading to shortages of materials, electronic components, and other supplies. This has caused manufacturing businesses to temporarily suspend operations, delay production, and increase manufacturing costs.

- Shortage of Human Resources: Economic fluctuations and unemployment support policies have caused workers to leave the manufacturing industry, leading to a serious shortage of human resources. This has made it difficult for manufacturing businesses to recruit and maintain a workforce.

Price Increases: Material, energy and logistics costs have increased due to factors such as geopolitical fluctuations, increased demand and supply chain disruptions. This has caused manufacturing costs to rise, affecting the profits of manufacturing businesses.

Fluctuations in Market Demand: Market demand is changing rapidly due to the impact of the COVID-19 pandemic and other economic factors. This forces manufacturing businesses to flexibly adjust to meet market demand, while minimizing inventory risks.

Increase in Logistics Costs: The cost of container shipping and other logistics services has increased due to container shortages, port congestion and supply chain disruptions. This causes manufacturing businesses to face higher product import and export costs.

Climate Change: Climate change causes extreme weather phenomena such as floods, droughts, and storms, affecting manufacturing activities and infrastructure of businesses. Manufacturing businesses need to take measures to adapt to climate change to ensure stable operations.

Too many difficulties and challenges for businesses since 2020

The manufacturing industry has been facing huge challenges since 2020. To overcome these difficulties, manufacturing businesses need to apply creative and flexible solutions to adapt to economic and societal changes. Digital transformation, advanced technology, and a sustainable supply chain are crucial solutions to help manufacturing businesses improve their competitiveness and develop sustainably in the future.

In a landscape filled with challenges and obstacles, the only viable solution is to leverage Manufacturing Digital Transformation (MDX) by applying new technologies such as MES, IoT, and AI to thoroughly address outstanding problems in manufacturing.

The fourth industrial revolution (Industry 4.0) is having a profound impact on every field, including the manufacturing industry. Digital transformation in manufacturing is an inevitable trend for businesses to improve competitiveness and develop sustainably in the new situation. The Manufacturing Execution System (MES) plays a key role in this digital transformation journey, contributing to optimizing manufacturing activities and increasing competitive advantages for businesses.

2. The Role of MES in Manufacturing Digital Transformation

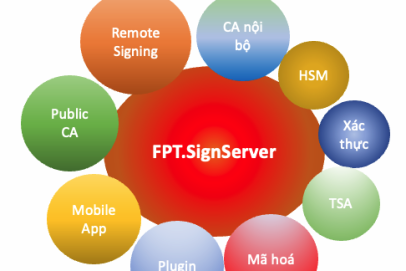

MES is a software system that manages and monitors manufacturing activities in real time, providing businesses with an overview of the manufacturing process from input to output. MES can be integrated with other systems such as ERP (Enterprise Resource Planning) and SCM (Supply Chain Management) to create a comprehensive manufacturing management system.

MES plays an important role in the digital transformation of manufacturing for the following reasons:

- Automating Production Processes: MES can automate manual tasks, helping to reduce errors and improve manufacturing efficiency.

- Optimizing Manufacturing Processes: MES can collect and analyze manufacturing data, helping businesses identify weaknesses and optimize manufacturing processes.

- Improving Product Quality: MES can monitor and control product quality throughout the manufacturing process, thus reduce the defect rate.

- Increasing Labor Productivity: MES helps employees work more efficiently, minimize downtime and increase productivity.

- Reducing Manufacturing Costs: MES helps businesses save costs on materials, energy, and labor.

- Enhancing Adaptability: MES helps businesses be more flexible in responding to changing market needs and developing new products.

Example

A smartphone factory is applying MES. A smartphone factory implementing MES can collect data from assembly lines, track the manufacturing progress of each phone, detect errors in real-time, and automatically adjust the manufacturing process to optimize efficiency. Thanks to MES, the factory can:

- Reduce assembly time for each phone by 15%.

- Increase the rate of qualified products by 10%.

- Save the raw material costs by 3%.

- Increase labor productivity by 12%.

3. Comparing MES with ERP and Other Management Solutions

- MES vs. ERP: MES and ERP are both crucial management systems for manufacturing businesses. However, MES focuses on real-time management of manufacturing operations, while ERP focuses on financial, accounting, and human resources management functions.

- MES vs. Other Management Solutions: MES can be integrated with other management solutions such as SCM and CRM (Customer Relationship Management) to create a comprehensive business management system.

Future Trends in MES Development

With the development of advanced technologies such as AI, IoT, and Big Data, MES is expected to continue to grow and play an even more important role in manufacturing digital transformation. Some notable trends include:

- AI-based MES: AI will be used to automate tasks in MES, predict issues, and optimize manufacturing processes.

- IoT-connected MES: MES will be connected to IoT sensors to collect real-time data about the manufacturing environment and machine status.

- Big Data-based MES: MES will use Big Data to analyze manufacturing data and provide deeper insights into operational efficiency.

4. Conclusion

Digital transformation in manufacturing is a long and challenging journey, but it also presents great opportunities for businesses. MES has been playing a key role in this journey, helping businesses effectively manage manufacturing activities, optimize processes, and increase competitiveness. Businesses that do not adopt MES are likely to fall behind in today’s volatile and rapidly changing market.

| Exclusive article by FPT IS Expert

Author Le Minh Quan – Director of digital transformation of akaMES factory, and Founder and CEO of akaMES |