Sustainable and Circular Textiles by 2030

In this article, we’ll cover:

- The Current Crisis in Textiles

- A Perfect Storm of Challenges

- Understanding Textile Value-chain

- Circularity Pathway under EU Green Deal Policy

- Utilize CEAP Pathway to Transform Your Business

- Step-by-Step Guideline for Sustainable Textile Production

- Case Study 1: Valérius

- Case Study 2: Black Fabric

- Case Study 3: Hugo Boss

- Case Study 4: Piacenza

1. The Current Crisis in Textiles

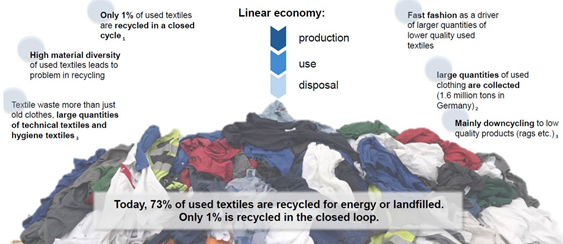

Today, 73% of used textiles are recycled for energy or landfilled. Only 1% is recycled in the closed loop.

The clothes we wear offer a glimpse into our personal style, but hidden beneath the seams is an unsettling reality. The textile industry, driven by the insatiable appetite of “fast fashion,” is confronting a multi-layered crisis that threatens its long-term viability. From staggering environmental pollution to social injustices and the pressures of evolving markets, the time for transformation is now. According to EU Green Deal (EPA,2022), the following facts indicating serious threats of textiles industry:

- In EU:

- It is one of the top three pressures on water and land use, and the top five in terms of raw material use and greenhouse gas emissions.

- Almost 9/10 Europeans (88%) think that clothing should be made to last longer

- About 5.8 million tonnes of textiles are discarded every year, equivalent to 11.3 kg per person

- An average of 20 to 35 jobs are created for every 1.000 tonnes of textiles collected for re-use, such as selling them second-hand

- Globally:

- Textiles production doubled between 2000 and 2015

- One full truckload of textiles goes to landfill or incineration every second

- Less than 1% of material used to produce clothing is recycled into new clothing

- Only upto 35% of all the microplastics released into the environment can be traced back to textile products.

2. A Perfect Storm of Challenges

The relentless pursuit of low-cost, trend-driven clothing has far-reaching consequences. These consequences expose a system rife with environmental degradation, social injustice, and vulnerabilities throughout the supply chain.

- Environmental and Social Toll: Textile production exacts a massive toll on the environment through pollution, vast water consumption, and greenhouse gas emissions. Additionally, fast fashion perpetuates labor exploitation, with workers in the global supply chain facing low wages, unsafe conditions, and even the specter of forced labor.

- Overproduction and Shifting Markets: Cheap, trend-driven clothing fuels overproduction and waste. This linear model faces further pressure from rising competition in low-cost countries, shifting consumer preferences toward sustainability, and the need for rapid digitalization to keep up with e-commerce demands.

- The Greenwashing Threat: Sincere commitments to sustainability by some companies become muddled in a sea of unsubstantiated “green claims” – eroding consumer trust and hindering authentic efforts.

- Unrecognized Standards: Even with robust legal frameworks for environmental and social standards in places like the EU, the global market often fails to reward producers operating at this high level, making it difficult to justify the investment.

- Skills Gap and Fragmentation: The industry needs a skilled workforce and a more coordinated approach. attracting younger talent while addressing fragmentation across research and the supply chain is urgent for innovation.

3. Understanding Textile Value-chain

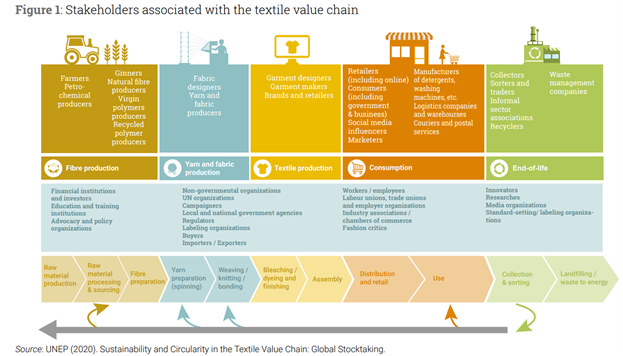

The textile value chain is complex. It starts with farmers and petrochemical companies supplying raw materials. Processors transform these into yarns and fabrics. Manufacturers design and assemble garments, while wholesalers and retailers bring them to consumers. Other stakeholders like regulators, NGOs, and research institutions are also important. They help drive sustainability, ethical practices, and innovation within the industry. Ultimately, consumer choices influence the entire value chain.

The intricate web of stakeholders we’ve explored highlights the extensive reach of the textile industry. However, this global reach comes at a cost, and the environmental impact across the apparel value chain is undeniable.

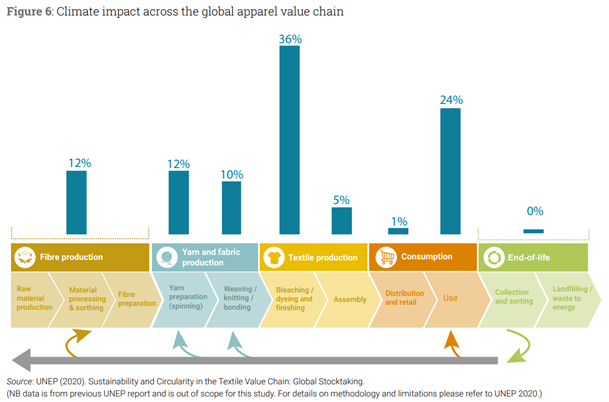

The complex journey of a garment, from raw materials to consumer, casts a long shadow on the environment. As illustrated in the life cycle breakdown each stage contributes to greenhouse gas emissions and other environmental burdens.

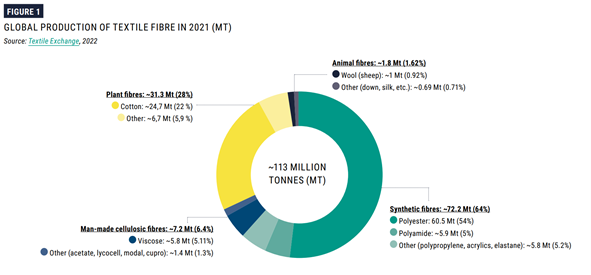

Production of raw materials, particularly synthetic fibers derived from fossil fuels, is a significant contributor. The image shows that fiber production accounts for 36% of the total climate impact. Processing these raw materials into yarns and fabrics is another source of emissions, at 12% according to the data. Fossil fuels are also heavily relied upon for textile production (spinning, weaving, knitting) which is reflected in the 12% share for this stage. These percentages highlight the environmental cost associated with manufacturing textiles. However, the story doesn’t end there. The consumer use and end-of-life phases also contribute to the overall climate impact.

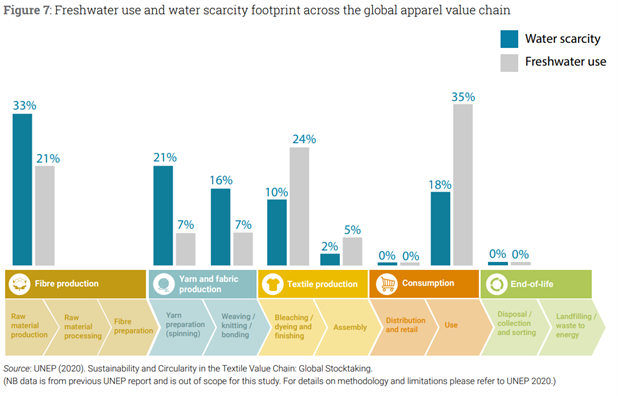

The substantial carbon footprint of the apparel industry is just one piece of the environmental puzzle. Next, we’ll delve into the equally pressing issue of freshwater use and water scarcity throughout the global apparel value chain.

The textile industry guzzles freshwater. Water-intensive cotton farming and polluting wet processing stages, like dyeing, leave a significant water scarcity footprint. This is especially harmful in areas already facing water stress, where textile production competes with local communities for this precious resource. Climate change intensifies this problem. The industry must adopt less water-intensive fibers, closed-loop systems, and water-efficient technologies to reduce its impact on freshwater supplies.

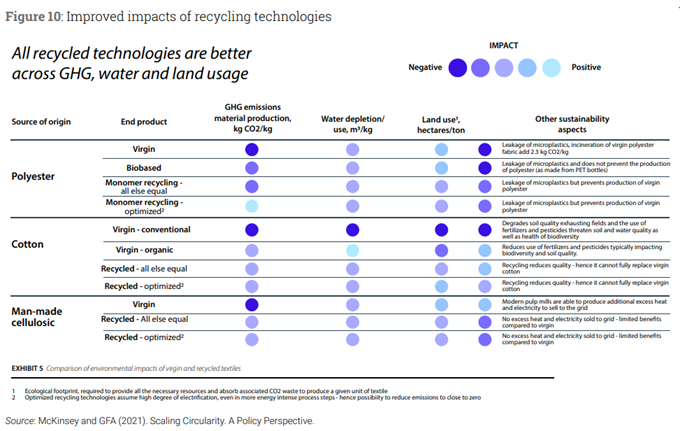

While significant challenges exist, the apparel industry isn’t without promising solutions. Let’s explore the improved impacts of recycling technologies and their potential to revolutionize the way we think about textiles.

Recycling technologies hold promise for the textile industry. Compared to virgin materials, recycled options greatly reduce greenhouse gas emissions, water use, and land requirements. For example, recycled polyester can achieve near-zero emissions compared to virgin polyester production. Recycling decreases the need for land to grow fibers and reduces water usage significantly. While challenges remain, continued investment in recycling technologies is crucial for a more circular textile system. These innovations offer the potential to minimize waste and greatly reduce the industry’s environmental footprint.

The promise of recycling technologies paves the way for a more sustainable future. Let’s shift gears and explore the concept of a circular pathway for textiles, a system designed to minimize waste and maximize resource efficiency.

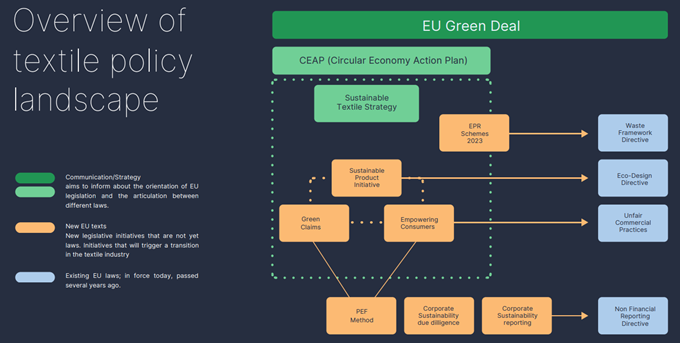

4. Circularity Pathway under EU Green Deal Policy

The EU Green Deal Circular Economy Action Plan (CEAP) aims to transform the textile industry towards a more sustainable and circular model.

This will likely necessitate significant changes for businesses, potentially impacting them in the following ways:

- Focus on Sustainable Practices: Businesses will likely need to prioritize eco-friendly materials, production processes, and end-of-life solutions to comply with stricter regulations and meet consumer demand for sustainable products.

- Investment in Innovation: The CEAP may incentivize investments in research and development for technologies that promote resource efficiency, recycling, and circularity within the textile industry.

- Transparency and Green Claims: Clearer regulations regarding environmental footprints and recycled content may be implemented. Businesses will need to ensure transparency throughout their supply chains to substantiate green claims.

- Consumer Awareness and Education: As consumers become more environmentally conscious, businesses may benefit from investing in initiatives that educate consumers about sustainable textile choices and proper garment care to extend product lifecycles.

Potential Opportunities

While the CEAP presents challenges, it also offers opportunities for businesses that embrace change and lead the way in sustainable textiles. Here are some potential benefits:

- Enhanced Brand Reputation: Consumers increasingly value sustainability. Businesses that prioritize eco-friendly practices can strengthen their brand image and reputation.

- Market Advantage: Early adopters of sustainable practices may gain a competitive edge in a market shifting towards circularity.

- Reduced Costs: Investing in resource efficiency can lead to long-term cost savings on materials and waste management.

The Green Deal Circular Economy Action Plan presents a roadmap for a greener future. Businesses in the textile industry that take advantage of the CEAP pathway have the potential to not just comply with regulations, but to truly transform their operations and unlock a new era of sustainable success.

5. Utilize CEAP Pathway to Transform Your Business

Collaborative Design and Business Models

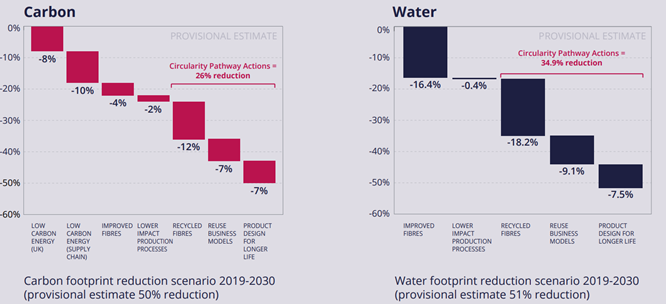

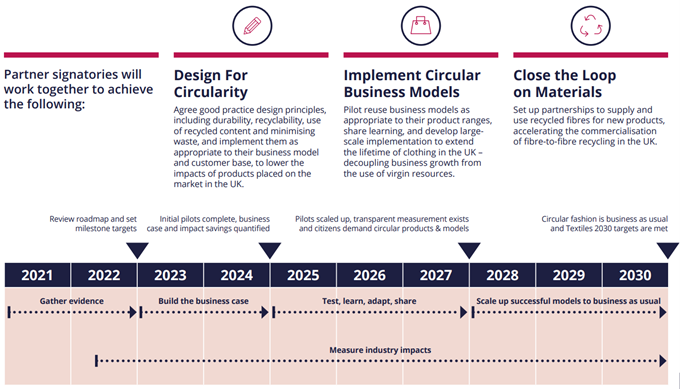

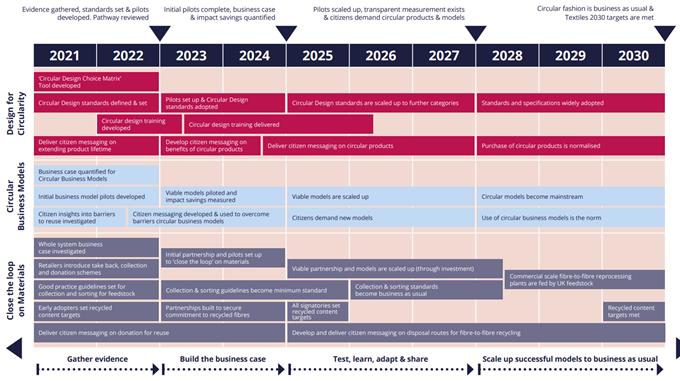

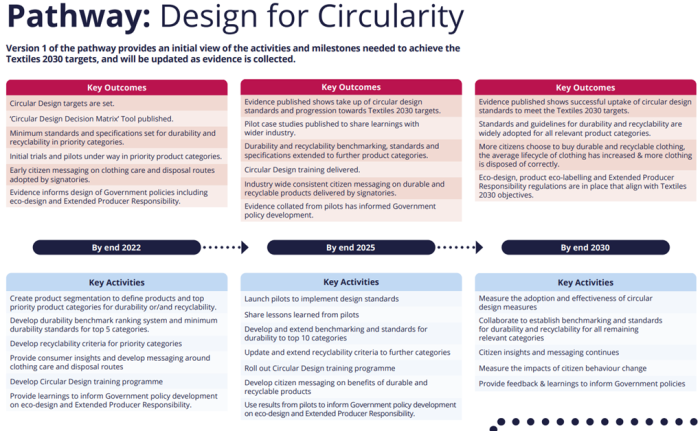

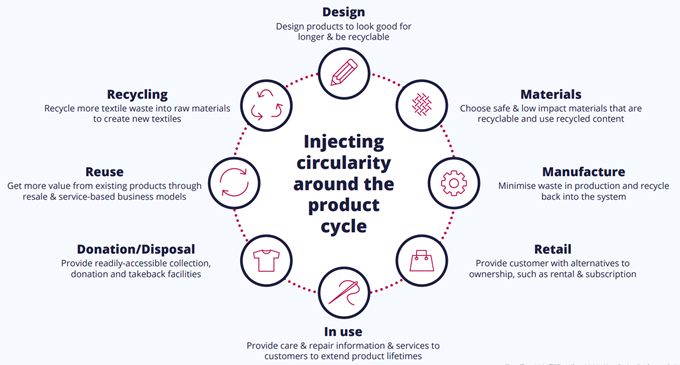

A cornerstone of the CEAP is design for circularity. This encourages businesses to develop products intended for longevity, reusability, and recyclability. The image highlights agreement on good design principles, like using recycled materials and minimizing waste. Collaboration with material suppliers, designers, and manufacturers is essential for implementing these principles effectively.

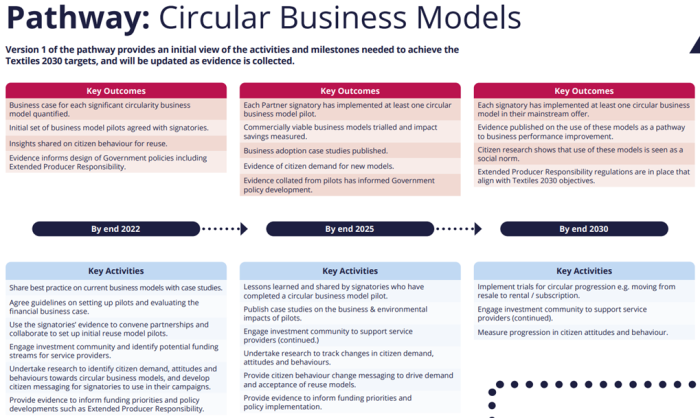

Pilot Programs and Knowledge Sharing

Testing new circular business models through pilot programs is another key aspect of the CEAP. The image shows this under “Pilot reuse business models.” Businesses can experiment with models like clothing rental services or take-back schemes for used garments. By sharing learnings through the CEAP framework, businesses can collectively accelerate the industry’s transition towards circularity.

Scaling Up Success and Transparency

Ultimately, the CEAP aims to make circular practices the norm across the textile industry. The image highlights “Scale up successful models to business as usual” as a key objective. Businesses that successfully implement circular models can expand these practices throughout their operations. Transparency throughout the supply chain is also emphasized in the image under “Transparent measurement exists.” By communicating their sustainability efforts clearly, businesses can earn consumer trust and build brand loyalty.

The path towards 2030 begins now. Let’s dive into the practical steps businesses must prioritize in 2023 and 2024 to create momentum and ensure long-term success in creating a circular textile industry.

2023 Actions for Businesses:

- Adopt Circular Design Standards: Companies should begin incorporating circular design principles (designing for longevity, recyclability, etc.) into their products. Accessing training and resources focused on circular design principles will be important.

- Develop Citizen Messaging: Collaborate to create engaging and clear messaging that highlights the benefits of circular models to consumers. Think about how best to communicate the value of recycled content or take-back programs.

- Pilot Viable Models: Initiate experimental programs around circular business models (rental, resale, repair programs). Carefully measure environmental impact savings compared to existing models.

- Build Partnerships to Close the Loop: Establish collaborations with textile recycling companies and other stakeholders to create closed-loop systems for used textiles.

2024 Actions for Businesses

- Scale Up Viable Models: Successful programs piloted in 2023 (those demonstrating positive environmental impact) should be expanded and integrated into regular operations. Continued investment may be necessary for scaling.

- Standardize Collection and Sorting: Participate in industry efforts to establish clear and efficient guidelines for collecting and sorting textiles for reuse and recycling.

- Deliver Citizen Messaging: Actively utilize the messaging developed in 2023 to educate consumers and shift demand toward circular models. This could be on product tags, in stores, or through broader marketing campaigns.

- Secure Commitments on Recycled Fibers: Companies should work with suppliers to establish targets for recycled fiber content and develop plans to achieve these goals.

Important Considerations:

- Collaboration is Key: Businesses can’t achieve these changes alone. Actively participate in the broader industry dialogue and collaborate with suppliers, policymakers, and other stakeholders within the value chain.

- Data is Essential: Track metrics to quantify the environmental impact of new initiatives and compare against the data being gathered as part of the broader Textile 2030 project. However, measuring environment impacts is challenging for most businesses. If you need automated tools for Automated Carbon Emission Calculation software, VertZéro is the most cost-effective tool to start with.

6. Step-by-Step Guideline for Sustainable Textile Production

By following the followings steps, textile companies can reduce their environmental impact, conserve resources, and create a more sustainable future for the industry. It’s important to note that achieving sustainability is a continuous journey, and there’s always room for improvement. However, by embracing these principles, businesses can make significant strides towards more eco-friendly textile production.

Sustainable textile production requires a holistic approach. Understanding your carbon footprint, prioritizing sustainable design and materials choices, and optimizing manufacturing processes are key. Ethical practices and transparency throughout the supply chain are essential to create a truly sustainable and circular textile industry. Textiles companies can refer to the following steps to prepare for Circular Business Model:

- Measure Carbon Emissions: Understanding your baseline carbon footprint is essential for effective change. Calculating emissions throughout the value chain identifies areas where the most significant reductions can be made. There are various tools and frameworks available to help businesses track their carbon emissions.

- Design for Durability and Recyclability: Sustainable production begins with thoughtful design. Products should be made to last, using high-quality materials and construction techniques that minimize waste. The recyclability of materials should also be considered at the design stage.

- Choose Safe and Sustainable Materials: Opt for natural fibers like organic cotton, linen, hemp, or recycled materials whenever possible. These materials tend to have a lower environmental impact than conventional materials and can often be recycled or composted at the end of their lifespan.

- Reduce Waste Throughout Production: Implement cutting technologies that minimize fabric waste during garment production. Additionally, scraps and leftover materials can potentially be reused in other products.

- Sustainable Manufacturing Processes: Energy-efficient technologies and processes should be used throughout manufacturing. This can include using renewable energy sources to power facilities and optimizing water usage in dyeing and finishing stages.

- Ethical Labor Practices: Sustainable production goes beyond environmental impact. Fair wages, safe working conditions, and respect for workers’ rights are essential throughout the supply chain.

- Transparency Throughout the Value Chain: Consumers increasingly demand transparency about the environmental and social impact of the products they purchase. Businesses should be willing to share information about their sourcing practices and manufacturing processes.

- End-of-Life Considerations: Design products that can be easily repaired or recycled at the end of their useful life. Some manufacturers are also exploring take-back programs where they collect used garments for recycling or reuse.

7. Case Study 1: Valérius

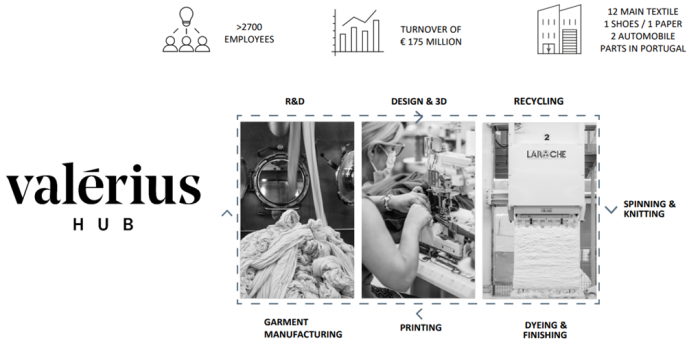

Valérius, a mid-sized textile company with a diversified product portfolio that includes apparel, shoes, and automobile parts produced in Portugal, is aiming to transform its business practices and embrace a circular model. They recognize the environmental and economic benefits of a circular economy and are committed to becoming a leader in sustainable textile production.

Challenges and Opportunities

Currently, Valérius faces several challenges related to sustainability. Their reliance on virgin materials like cotton, leather, and various fibers for clothing and car parts contributes to resource depletion and environmental pollution. Additionally, waste generated during production and at the end-of-life stages of their products adds to the industry’s environmental burden.

Transitioning to a circular model presents exciting opportunities for Valérius. By adopting circular principles, the company can reduce its environmental impact, improve resource efficiency, and potentially gain a competitive edge in the marketplace.

Valérius’ Circular Strategy

Valérius’ circular strategy focuses on three key pillars:

- Design for Circularity: The company will redesign its products for longevity, repairability, and recyclability. For clothing, this may involve using high-quality, durable fabrics and timeless designs that can be easily mixed and matched. For shoes, they could explore using components that can be resolved or replaced. In car parts, Valérius could design parts for easier disassembly and remanufacturing. Valérius will also explore using recycled materials in their products, further reducing their reliance on virgin resources.

- Sustainable Production Practices: Valérius will invest in energy-efficient technologies and production processes to minimize water and energy consumption throughout their manufacturing operations in Portugal. Additionally, they will implement strict waste reduction measures across all product lines.

- Post-Consumer Product Management: Valérius will explore innovative take-back programs where they collect used clothing, shoes, and car parts after they reach the end of their useful life. These used materials can then be recycled or downcycled into new products, closing the loop on the textile lifecycle. For clothing and shoes, this might involve collecting garments for disassembly and material recycling. For car parts, Valérius could explore partnering with car repair shops to collect parts for refurbishment or recycling.

Collaboration is Key

Valérius recognizes that transitioning to a circular model requires collaboration across the textile industry. They plan to partner with suppliers, recyclers, and other stakeholders to develop a robust circular ecosystem in Portugal. This could involve collaborating with fiber producers to secure recycled materials, partnering with waste management companies to develop effective collection systems, and working with research institutions to explore innovative recycling technologies.

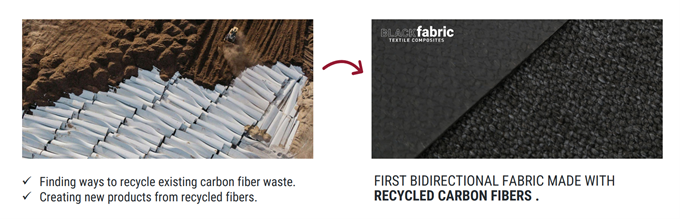

8. Case Study 2: Black Fabric

Blackfabric, a pioneering manufacturer of carbon fiber-reinforced fabrics based in the European Union, is on a mission to revolutionize the composites industry with a commitment to circularity. Recognizing the limitations of linear production models, Blackfabric is actively transforming its operations to embrace a more sustainable future.

Challenges and Opportunities

The composites industry, while offering high-performance materials for various applications, faces significant sustainability challenges. Traditional production methods rely heavily on virgin fossil fuels for energy and raw material extraction. Additionally, disposal of composite waste often involves landfilling or incineration, contributing to environmental pollution.

Blackfabric recognizes that a circular approach presents exciting opportunities. By adopting circular principles, the company can significantly reduce its environmental impact, improve resource efficiency, and potentially unlock new markets seeking sustainable composite solutions.

Blackfabric’s Circular Strategy

Blackfabric’s circular strategy focuses on three key areas:

- Sustainable Material Sourcing: Blackfabric is actively exploring ways to incorporate recycled materials into their carbon fiber fabrics. Partnerships with suppliers developing recycled carbon fiber precursors are crucial in this endeavor. This shift will reduce reliance on virgin fossil fuels and minimize the environmental footprint associated with raw material extraction.

- Design for Disassembly and Reuse: Traditionally, composite components are difficult to disassemble and reuse at the end of their lifespan. Blackfabric is investigating innovative design solutions that facilitate disassembly and enable reuse of carbon fibers in new products. This approach can significantly extend the lifecycle of composite materials and minimize waste generation.

- End-of-Life Recycling Technologies: Blackfabric recognizes the importance of developing robust recycling technologies for composite materials. The company is exploring collaborations with research institutions and industry players to advance technologies for efficient recycling of carbon fiber waste into usable materials. This closed-loop system is essential for a truly circular composites industry.

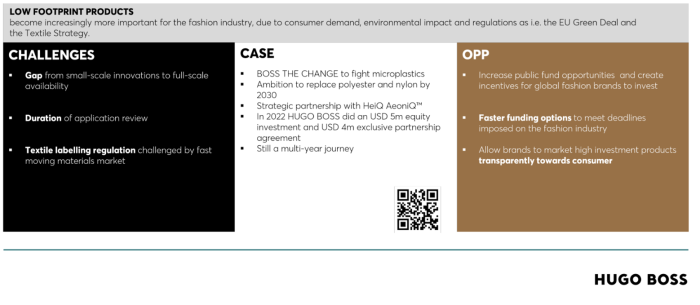

9. Case Study 3: Hugo Boss

Hugo Boss, a world-renowned fashion brand known for its premium apparel and accessories, is aiming to transform its business practices and embrace a circular model aligned with the ambitious goals outlined in the Textile 2030 initiative. This initiative provides a roadmap for the industry to achieve significant progress in sustainability by 2030.

Challenges and Opportunities

The fashion industry faces significant sustainability challenges. Linear production models rely heavily on virgin resources, contribute to textile waste, and often lack transparency throughout the supply chain.

Hugo Boss recognizes that transitioning to a circular model presents exciting opportunities. By embracing circularity, Hugo Boss can reduce its environmental impact, improve resource efficiency, and potentially enhance brand reputation among increasingly eco-conscious consumers.

Hugo Boss’s Circular Strategy

Hugo Boss’s circular strategy focuses on several key areas aligned with the Textiles 2030 initiative:

- Design for Circularity: From 2023 onwards, Hugo Boss will integrate circular design principles across new product lines. This means designing garments for durability, repairability, and recyclability. The image highlights “Circular Design Decision Matrix Tool published” as a key resource in 2023 that Hugo Boss can leverage. For example, the company could explore using high-quality, recycled, or easily recyclable materials and design clothing with modular components that can be easily upcycled or repaired.

- Extending Product Lifespan: Hugo Boss will explore initiatives to encourage consumers to extend the lifespan of their clothing. This could include offering repair services, garment care tips, and take-back programs for pre-owned clothing. The image shows “Develop citizen messaging on benefits of circular products” as an important step in 2023 for educating consumers on these initiatives.

- Closing the Loop on Materials: Hugo Boss will collaborate with partners throughout the supply chain to develop closed-loop systems for textiles. The image highlights “Initial partnership and pilots set up to ‘close the loop’ on materials” as a key action in 2023. This could involve working with recycling companies to develop processes for transforming textile waste into new materials for Hugo Boss products.

- Transparency and Citizen Engagement: Transparency throughout the supply chain is essential for building consumer trust in circular practices. Hugo Boss will collaborate with stakeholders to improve traceability and communicate its circularity efforts to consumers effectively. The image shows “Deliver citizen messaging on circular products” as an ongoing action from 2023 through 2027.

Aligning with Textile 2030

By implementing these strategies and aligning its efforts with the Textile 2030 initiative, Hugo Boss can become a leader in circular fashion. The collaborative approach envisioned in the initiative offers a promising pathway for a more sustainable future for the fashion industry.

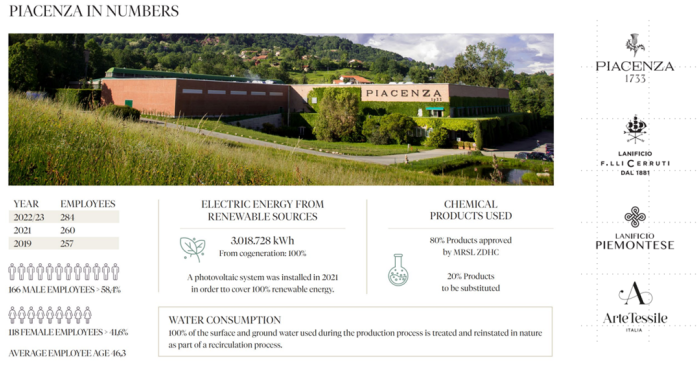

10. Case Study 4: Piacenza

Piacenza 1733, a historic Italian textile company renowned for its high-quality cashmere and wool fabrics, is embarking on a journey towards a more sustainable and circular business model. The company’s commitment to environmental responsibility is evident in their recent acquisition of Lanificio Piemontese, a company specializing in recycled fiber production. This strategic move positions Piacenza 1733 to play a leading role in the future of sustainable textiles.

Challenges and Opportunities

The textile industry faces significant sustainability challenges. Traditional practices rely heavily on virgin resources, contribute to textile waste generation, and often lack transparency in supply chains. Piacenza 1733 recognizes these issues and sees them as opportunities to innovate and differentiate itself in the marketplace.

Piacenza 1733’s Sustainability Strategy

Piacenza 1733’s sustainability strategy focuses on three key pillars, as highlighted in the information within the image:

- Increased Use of Recycled Fibers: The acquisition of Lanificio Piemontese is a major step towards this goal. By incorporating recycled fibers into their product lines, Piacenza 1733 can reduce reliance on virgin materials and minimize the environmental impact associated with raw material extraction. The image shows a target of having 20% of products made with recycled fibers by 2024.

- Transparency Throughout the Supply Chain: Building trust with consumers requires transparency about sourcing practices and environmental impact. Piacenza 1733 is committed to increasing traceability throughout their supply chain and communicating their sustainability efforts clearly to consumers. The image shows 100% of chemical products used meeting MRSL ZDHC standards by 2021, demonstrating their commitment to responsible chemical use.

- Investing in Renewable Energy: Piacenza 1733 recognizes the importance of reducing its environmental footprint across all operations. The image shows that by 2022/23, the company achieved 100% of its electricity use coming from renewable sources through a combination of photovoltaic systems and cogeneration technologies. This investment in renewable energy demonstrates Piacenza 1733’s commitment to reducing its carbon footprint.

A Commitment to Circularity

The image also highlights Piacenza 1733’s commitment to exploring opportunities for closing the loop on textile waste in the future. While specific details aren’t provided, this could involve collaborating with partners to develop take-back programs for used textiles or supporting initiatives that promote upcycling and recycling of textile materials.

Leading by Example

Piacenza 1733’s sustainability efforts position them as a leader in the transition towards a more circular textile industry. By increasing reliance on recycled fibers, investing in renewable energy, and embracing transparency, Piacenza 1733 serves as an inspiration for other textile companies to adopt more sustainable practices. The company’s commitment to environmental responsibility bodes well for the future of the industry.

| Exclusive article by FPT IS expert

Author Pham Tuan – Director of VertZero product |